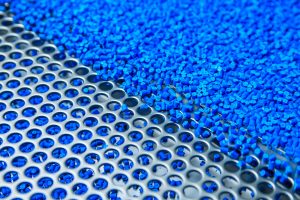

Cri-Tech offers a broad line of high-performance fluoroelastomers (FKM & FFKM), fluoro-TPEs (cross-linkable) and TPVs, fluoroplastic compounds/blends (ETFE, PDVF, FEP, PFA), specialty masterbatches, HNBR & other polymer materials. Tested, proven, and ready for processing.

Fully formulated high performance fluoroelastomer (FKM) compounds developed, tested, and ready for processing. Cri-Tech offers the most extensive line of proven FKM products of any custom formulator or compounder. Learn More

Melt processable Fluoro – Thermoplastic Elastomers (F-TPEs) and Vulcanizates (F-TPVs) are blends of fluoroplastics and fluoroelastomers developed to meet a wide range of applications including Automotive, Wire & Cable, Chemical Industry, and Consumer goods. Products can be used as-is, or specific grades are capable of e-beam cross-linking for increased performance. Learn More

Fluoroplastics (PFA, FEP, EFEP, ETFE, PVDF) including blends with PEEK and other high-performance materials for multiple applications including electrically and thermally conductive. Cri-Tech has access to unique technology and expertise relating to fluoromaterials. Learn More

Cri-Tech’s Static Dissipative/Conductive Cri-plastMP™ Thermoplastic (PFA, ETFE, TPEs) and Cri-Line® Thermoset Elastomer (FKM & HNBR) Compounds can now be tailored to meet your most demanding ESD application requirements.

Hydrogenated Nitrile (HNBR)

HNBR rubber compounds offer excellent value to performance properties.

Cri-Spersion Compounds

Cri-Spersions are dispersions of activators or other rubber chemicals on a fluoroelastomer base. These unique proprietary products, first developed by Cri-Tech for its fully formulated FKM compounds, are available as additives.

Contact Us

Our sales and technical staff will be glad to discuss your application and help select a product that meets your needs.

If your specification or application is not served by one of Cri-Tech’s standard products, we will develop a custom solution for you.