Cri-Tech is the leader in full-service formulation development and custom compounding of high-performance elastomers, thermoplastics and specialty products. A wholly-owned, independently operating, subsidiary of Daikin America, Cri-Tech continues to expand its specialty product portfolio and compounding services by leveraging unique materials and compounding expertise. Offering a broad standard product portfolio along with custom formulated solutions, Cri-Tech prides itself on working closely with customers to select or develop a material that meets their specifications.

Products

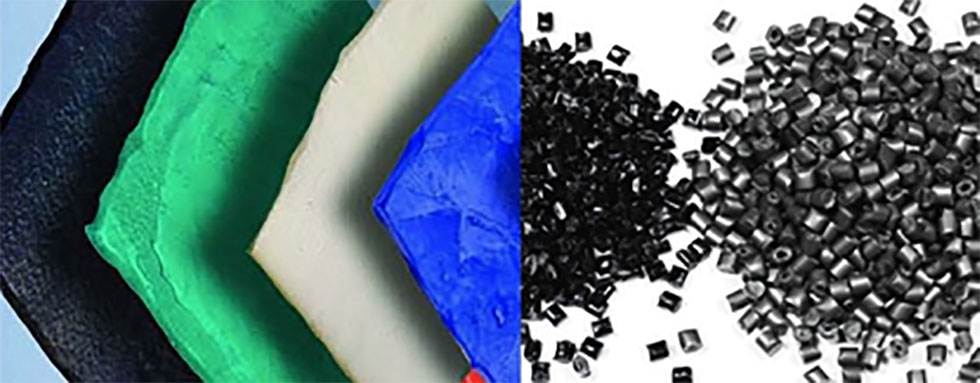

Cri-Tech offers a broad line of high-performance compounds including:

- Fluoroelastomers (FKM & FFKM), HNBR & other specialty thermoset elastomers

- Fluoroplastic compounds (ETFE, PDVF, FEP, PFA) & blends

- Cross-linkable Fluoro-TPEs (F-TPE) and TPVs

- Static Dissipative/Conductive Compounds

- Specialty Masterbatches

Solutions

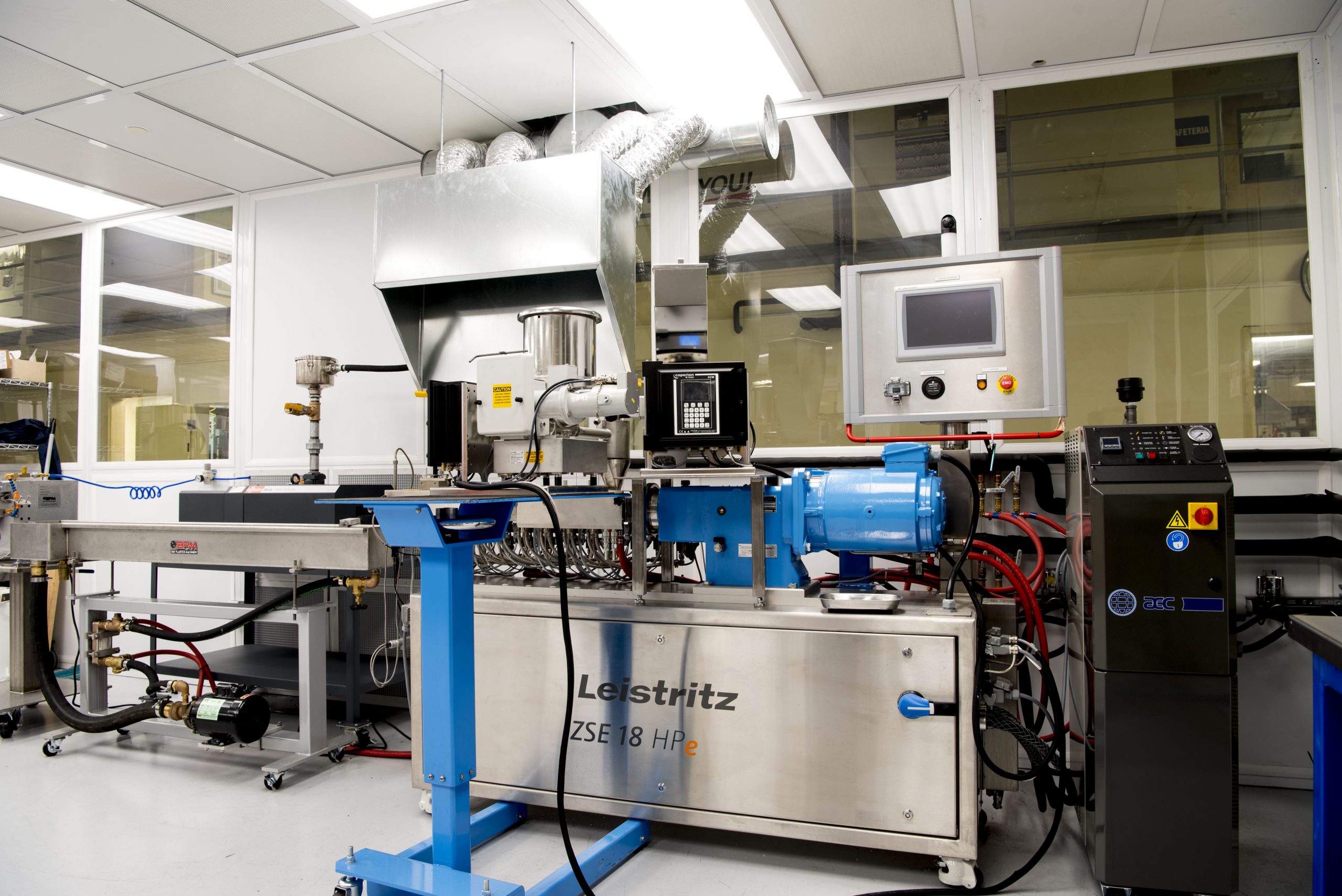

Flexible Solutions to meet your specific business needs:

- Custom Rubber & Thermoplastic Compounding.

- Extensive standard product portfolio.

- Expert Toll Manufacturing.

- Pre-Colored Compounds.

Applications

Market Experience

Cri-Tech has continued to grow its core business in Automotive, Wire & Cable, Oil & Gas, and Aerospace, while investing in a clean compounding facility to expand into Food Contact, Pharmaceutical, Medical, and high-end Consumer Products.

There are no current openings, please check back soon.